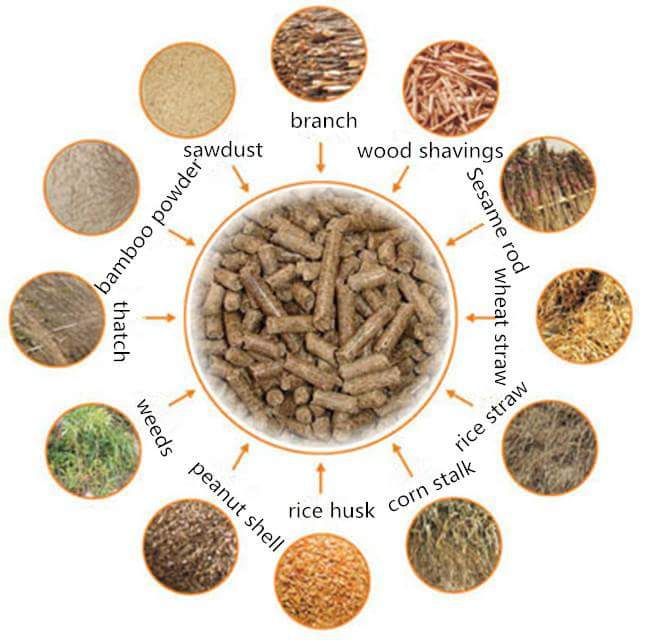

In fact,neary all kinds forestry waste and agriculture waste could be used as raw material.Such as wood log, wood branches ,wood chips, wood sawdust, sawmill processing waste-wood shavings, rice husk, rice strawm corn stalk.bamboo ,alfalfa .....

Of course, different raw material need different processing steps.

For press into pellets by a wood pellet mill machine, the size of raw material need to less than 10mm.

And moisture content should better 12%-15%.

So if size is bigger or moisture content is higher,

a pre-treatment section is necessary.

Pre-treatment section usually is :Chipping Section-Grinding Section and Drying Section.